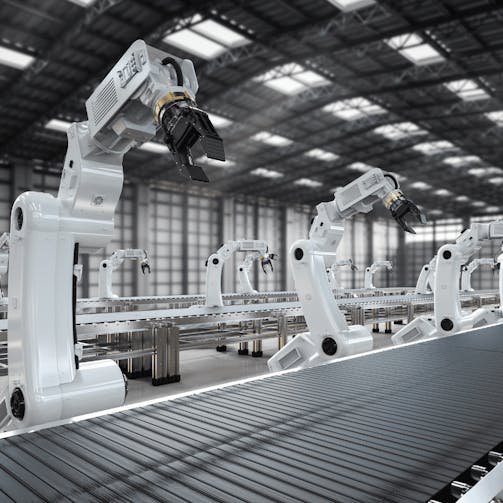

We Are Your Experts for Machinery and Industrial Automation Repair

The Art and Science of Repairing and Maintaining Industrial Automation Machinery

Operator Training

Training operators on the proper use of machinery is crucial. We conduct training sessions to teach them how to operate the equipment safely and efficiently, recognize early signs of trouble, and perform basic maintenance tasks.

Technical Support

Even with the best training, there will always be times when expert assistance is needed. We offer ongoing technical support to our clients, providing guidance over the phone or via remote access when possible. This ensures that they have access to the expertise they need, whenever they need it.

Staying Current with Industry Trends

The field of industrial automation is constantly evolving, with new technologies and best practices emerging all the time. To provide the best possible service to our clients, we stay current with industry trends and continuously update my skills and knowledge.

Continuing Education

We regularly attend workshops, seminars, and training courses to stay up-to-date with the latest advancements in industrial automation. This ongoing education helps us stay ahead of the curve and ensures that we can offer my clients the most effective solutions.

Networking and Collaboration

Networking with other professionals in the field is also important. We participate in industry forums, attend trade shows, and collaborate with other experts to share knowledge and learn from their experiences. This collaborative approach helps us stay informed about new technologies and best practices.

Preventive Maintenance

While repairs are sometimes unavoidable, preventive maintenance is key to minimizing downtime and extending the lifespan of industrial automation machinery. We work with our clients to develop a comprehensive maintenance schedule tailored to their specific equipment and operational needs.

Regular Inspections

Regular inspections are the cornerstone of preventive maintenance. We conduct detailed inspections at scheduled intervals, checking for signs of wear, ensuring all connections are secure, and verifying that all components are functioning correctly. This proactive approach helps identify potential issues before they become major problems.

Cleaning and Lubrication

Keeping machinery clean and well-lubricated is essential for smooth operation. Dust, dirt, and debris can accumulate over time, causing components to overheat or wear out prematurely. We ensure that all moving parts are properly lubricated and that the machinery is kept clean and free of contaminants.

Software Updates

Just like any other computerized system, PLCs and HMIs require regular software updates to fix bugs, improve performance, and add new features. We stay up-to-date with the latest software releases from manufacturers and ensure that my clients' systems are always running the most current versions.

Training and Support

In addition to hands-on maintenance and repairs, we also provide training and support to my clients' staff. This empowers them to handle minor issues on their own and ensures that they understand the importance of regular maintenance.

Diagnostic Tools

Next, we use diagnostic tools to delve deeper. Multimeters, oscilloscopes, and specialized software for PLCs and HMIs are essential in this phase. These tools help us measure electrical signals, check for continuity, and analyze the performance of various components. For instance, if a motor is not running as expected, we might use an oscilloscope to check the waveform of the power supply and ensure it matches the required specifications.

Troubleshooting and Repair

Once we have a clear understanding of the issue, the troubleshooting process begins. This involves systematically testing different components and subsystems to isolate the faulty part.

Electrical Components

For electrical issues, we start by checking the power supply and ensuring that all connections are secure. Loose or corroded connections can cause intermittent problems that are difficult to diagnose. We also check for blown fuses, tripped circuit breakers, and other common electrical faults.

PLCs and HMIs

When dealing with PLCs and HMIs, software issues are often the culprit. we connect my laptop to the PLC and use diagnostic software to check for error codes and review the program logic. Sometimes, a simple software update or reconfiguration can resolve the issue. In other cases, we might need to replace a faulty module or reprogram the PLC.

Mechanical Components

Mechanical issues require a different approach. We inspect moving parts for signs of wear, lubrication issues, or misalignment. Bearings, belts, and gears are common points of failure in industrial machinery. Replacing these components and ensuring proper alignment and lubrication can often restore the machine to full functionality.

As professional electricians specializing in industrial automation, our work is both challenging and rewarding. The intricate dance of diagnosing, repairing, and maintaining complex machinery requires a blend of technical expertise, problem-solving skills, and a deep understanding of the systems at play. In this blog post, I will take you through the process of how we repair and maintain industrial automation machinery for my clients, ensuring their operations run smoothly and efficiently.

Understanding Industrial Automation Machinery

Industrial automation machinery encompasses a wide range of equipment used to automate manufacturing processes. This includes programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, actuators, and various types of motors and drives. These systems are designed to increase efficiency, reduce human error, and enhance productivity. However, like any complex system, they require regular maintenance and occasional repairs to function optimally.

Initial Assessment and Diagnosis

The first step in any repair or maintenance task is a thorough assessment. When a client contacts us with an issue, we start by gathering as much information as possible about the problem. This includes understanding the symptoms, the history of the machinery, and any recent changes or events that might have contributed to the issue.

Visual Inspection

A visual inspection is often the first hands-on step. We look for obvious signs of wear and tear, such as frayed wires, loose connections, or physical damage to components. This can provide immediate clues about the nature of the problem.

When you need repairs to yiour machinery and industrial automation equipment, think of us first to install all the necessary components to get and keep you up and running.

We Do All These Tasks and More:

- Diagnose and troubleshoot electrical issues in industrial machinery and automated systems

- Repair and maintain electrical components of industrial equipment, including motors, transformers, control systems, and automated machinery

- Install, upgrade, and configure electrical wiring, components, and systems for industrial automation equipment

- Work with programmable logic controllers (PLCs) and automation controls to program, maintain, and repair automated industrial systems

- Perform preventive maintenance on electrical systems and machinery to ensure optimal performance and prevent breakdowns

- Test and calibrate newly installed or repaired equipment to ensure proper functioning and compliance with safety standards

- Upgrade existing systems to improve efficiency, incorporate new technologies, or meet changing production requirements

- Ensure compliance with safety regulations and industry standards when working on high-voltage systems and potentially hazardous industrial environments

Conclusion

Repairing and maintaining industrial automation machinery is a complex and demanding task that requires a deep understanding of both electrical and mechanical systems. By combining thorough assessments, systematic troubleshooting, and proactive maintenance, we help our clients keep their operations running smoothly and efficiently. Through ongoing training and support, we empower them to take an active role in maintaining their equipment, ensuring long-term reliability and performance. As the field of industrial automation continues to evolve, we remain committed to staying current with the latest trends and technologies, providing our clients with the highest level of service and expertise.